1.The main technical parameters: |

Product name | Vacuum hot press furnace |

Equipment form | Vertical construction |

Door opening method | Side door opening (front pick-up) |

Heating form | Induction heating |

Maximum | 40KW±10% (based on actual power) |

power |

|

Service size | Φ496X520mm (diameter x length) |

Number of warm zones | 1 warm zone |

Maximum temperature | 1600 ℃ |

Rated temperature | 1600 ℃ or less |

Ultimate vacuum | 5 x 10-3Pa (empty furnace, cold, purified) |

Pressure rise rate | ≤2Pa/h |

Diameter of indenter | Φ75 mm |

Maximum pressure | 20T (digital display) |

Pressure stroke | 0 to 40mm |

Pressurized mode | Unidirectional pressure (down pressure) |

Pressure fluctuation | Plus or minus 0.1 MPA or less |

Lifting speed | ≤5mm\S |

Temperature control accuracy | + / - 1 ℃ |

Temperature control meter | Digital display temperature program controller |

Temperature easurement | Infrared thermometers |

Protective atmosphere | Argon or high purity nitrogen gas |

Charging pressure | 0.03 MPA or less |

Explosion-proof pressure | 0.005MPA (adjustable upper and lower limits) |

Water quality requirements | PH 7.0 ~ 8.5, suspended solids < 100mg/L, total hardness CaO < 10mg equivalent /L, dissolved solids < 30mg/L, conductivity < 500μS/cm |

Requirem ents for use | The altitude is below 1000M, the ambient temperature is 0~45 degrees, and the humidity is 15%~45%. |

Working power supply | AC 380V Three-Phase, 50/60 Hz |

Overall dimensions | The heating furnace size (1760x1390x1900) is based on the actual product size |

2. Equipment structure: |

Structure | Vertical side door opening structure, the control part is located on the right side of the body; The whole machine adopts module integrated structure; A total of furnace body module, control module, vacuum system module, hydraulic system module, movement, assembly, maintenance is very convenient; |

Furnace Body | The furnace body adopts double-layer cylinder vertical structure, and the chamber is made of 304 stainless steel. And after precision polishing treatment, water is cooled between the inner and outer walls to ensure that the temperature of the furnace wall is lower than 55℃. The furnace body is provided with a vacuum air outlet, temperature measuring hole, electrode hole, pressure head sealing seat, etc.; |

Furnace door structure | The furnace door adopts double- layer water-cooled side opening structure (convenient loading and unloading abrasives), the inner and outer walls are made of 304 stainless steel and have been precision polished. The water is cooled between the inner and outer walls, and the furnace door is provided with an observation window. |

Head seal structure | According to customer production process; The equipment adopts the lower pressure structure, which can effectively avoid the vibration of the material when the customer puts the material in the process of pressure movement; The indender adopts the bellows sealing mechanism, which is more stable and reliable and easy to maintain and low cost compared with the skeleton seal and Wilson seal ring on the market; |

Heating and insulation system | Heating system adopts induction heater; Uniformly distributed induction coil fixing mode; It can ensure the best temperature uniformity and uniform heating of the workpiece in the furnace, and facilitate the maintenance and replacement of the heating body. The heat preservation system adopts carbon felt heat insulation screen for heat preservation. |

Heating electrode | The design of the water-cooled electrode not only ensures a good seal and insulation with the furnace body, but also has good contact with the connecting line of the power supply, and is easy to disassemble. The water cooling device in the electrode can reduce the temperature of the conductive joint and prevent the burning of the vacuum sealing material, which affects the vacuum degree in the furnace. The new electrode structure avoids the phenomenon of copper pipe corrosion and welding joint corrosion and water leakage during long-term use. |

Pressuri zation system | The press is composed of four columns and upper and lower beams, the pressure cylinder is fixed on the beam, the furnace body is supported on the furnace frame, and is fixed with the lower beam, the beam is strictly machined to ensure the pressure accuracy of the upper and lower pressure head. The pressure system is composed of hydraulic station, pressure cylinder, pressure sensor, pressure displacement sensor, etc., and is controlled by the solenoid valve through the control system; The instrument can automatically adjust the pressure through the proportional relief valve, so as to achieve pressure regulation and pressure preservation. |

Vacuum system | In order to reduce the area of the equipment and the weight of the switchboard and the convenience of maintenance, under the condition of ensuring the same performance, the vacuum system is now using a molecular pump, bipolar rotary vane vacuum pump, high vacuum baffle valve, vacuum gauge, vacuum pressure valve, vacuum pipe, etc., and has a charging interface. In order to reduce the vibration of the furnace body, the connection between the vacuum pipe and the pump is made of metal bellows, and the vacuum measurement is measured by the resistance vacuum gauge. Reasonable design of vacuum unit can make the vacuum degree of the equipment up to 5X10-3pa; The vacuum system valves are pneumatic control, all key switch points are written into the touch screen, integrated operation; The vacuum unit has an integrated frame; Ensure that the vacuum system can be fixed independently; |

Rapid cooling system | The equipment is equipped with a rapid cooling device, which directly passes inert gas into the heating furnace to bring out the heat in the furnace through the heat insulation screen (because the furnace body has a sealing device as a whole, it will not affect the sealing of the furnace body); The gas is eliminated through the outlet interface of the water cooling device; To ensure the service life of its solenoid valve, and operation safety; |

Water cooling system | Water cooling system consists of inlet water pipe, return water pipe, valve, line, etc. Through the pipeline supply vacuum unit, furnace body, heating electrode and so on. The water cooling system is connected with the control system, and when the water is low, the sound and light alarm is automatically carried out, and the heating power supply function is automatically cut off to ensure the safety of the equipment. The backup water device of the equipment is prepared by the customer, and the backup water flow rate is ≥ 10m3/h. |

Control system | Temperature control is through the digital display temperature program controller according to the user-set process curve, the implementation of automatic control temperature, and with PID self-tuning function, can also be manually controlled according to user needs. The control system adopts IEC standard, selected electrical components and measuring components, simple and intuitive operation. Including: the whole control cabinet 1 set, including: button, indicator light, alarm, air switch, contactor, cable bridge and so on. The whole electric furnace in the working state, with water pressure under pressure, over temperature, over current automatic interlock and alarm, protection and cutoff the main power supply function. The alarm state is the screen display mode. |

Automatic control | The control system is divided into manual automatic dual mode; According to customer requirements: All temperature, pressure procedures, vacuum systems and press systems are integrated in the touch screen; Customers only need to start with one key, the equipment can run the vacuum unit of the equipment and pressure, pressure and other process actions. |

Temperature monitoring | In order to allow customers to better observe the temperature of the workpiece in the hot press furnace, the equipment is designed with infrared thermometer to display the temperature in the furnace in real time, so that customers can adjust the process according to the actual situation; |

Data recording system | According to the customer process, the touchscreen needs to record the data, and the history record can be consulted (material recorder function) : 1: main control temperature PV,SV; 2: vacuum value; 3: press value PV,SV; 4: gas lifting pressure; The above temperature is required to have the effect of data report and curve display, which is convenient for customers to read; |

Security protection | Equipment with over temperature, pressure over pressure, gas path over pressure, break even alarm automatic power off, over current, leakage protection function, simple operation, safe and reliable; |

3.Installation conditions demand |

Power supply requirements | 1: Power demand: AC380V±10% 50HZ three-phase five-wire system; 2: lifting equipment: 2 tons: 3: Water source: a, consumption: 10m3/h b, water pressure: 0.25~0.4Mpa c, inlet water temperature: ≤30℃ |

Installa tion site requirem ents | 1: After the equipment, left and right distance from the surrounding wall shall not be less than 600mm; 2: the ambient temperature is between -10 and 75℃; 3: the relative humidity of the surrounding environment does not exceed 85%; 4: there is no conductive dust, explosive gases and corrosive gases that seriously damage metals and insulating materials around the furnace; 5: there is no obvious tilt, vibration and bumpy placement surface; |

4.Installation and commissioning |

1.Party A is responsible for the foundation, the air source, and the incoming cable before the bus input of Party B's electric control cabinet. The inlet and return water shall be connected to the total inlet and return water outlet of Party B's cooling water tank. After all the preparatory work is completed, Party B shall be notified to carry out installation and commissioning. 2.The equipment shall be installed and debugging at the Buyer's site in the manner organized by the Seller and in cooperation with the Buyer, and shall meet the Buyer's requirements for normal use; Acceptance standards shall be accepted according to the equipment technical agreement signed by both parties. The pre-acceptance shall be carried out at the site of the seller and sent to the site of the buyer after passing the inspection. The final acceptance shall be carried out after the buyer's site installation and debugging is qualified; 3.After the acceptance work is completed, the two parties shall jointly sign the final acceptance report of the equipment. |

5. After-sales and service |

Service guarantee: | Product manufacturing and testing in strict accordance with the relevant standards, and quality records can be checked; Each device has a unique manufacturing number, and a user profile is established. |

18 months warranty (except related consumable parts); Spare parts available at lifetime cost. |

During the warranty period, if the equipment fails, our company will reply within 2 hours and provide emergency solutions; Major equipment failure within 24 hours to arrange professional on-site service. |

Regular return visit service: Provide regular telephone return visit or door-to-door return visit service. |

We provide free software upgrade and update service, so that the equipment is always in the leading position in China. |

During the commissioning period, we provide free installation operation training and technical support, the training content generally includes: 1: the correct operation process of the product; 2: precautions in operation; 3: Solving common problems; 4: domestic and foreign technical knowledge of related products; |

6. Packaging and transportation |

Wooden packing box packaging, automobile transport to the customer's designated place (only domestic); |

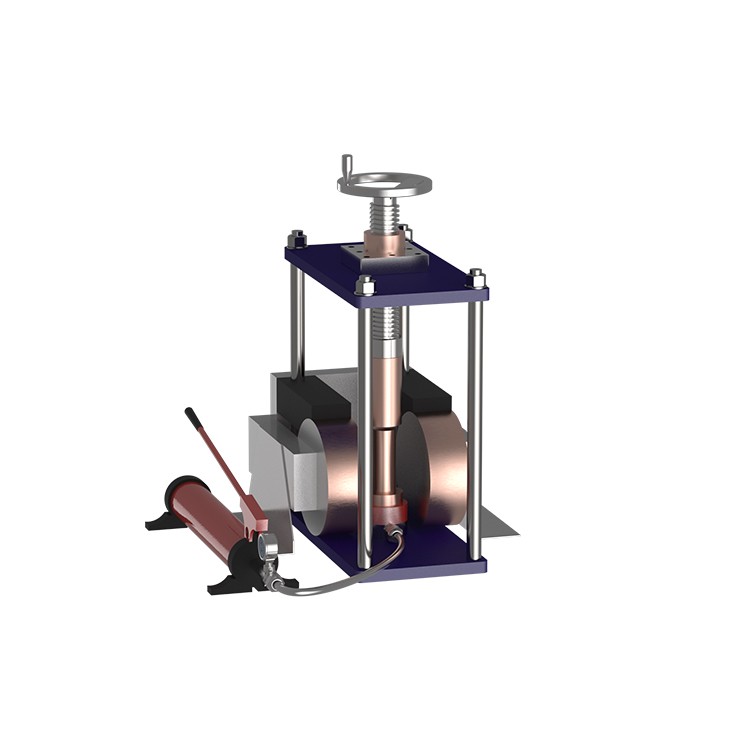

7. Similar products picture |

|

|

|

|